Cargo securing methods

Blocking

Blocking means that the cargo is stowed against fixed blocking structures and fixtures on the CTU. Clumps, wedges, dunnage, dunnage bags and other devices which are supported directly or indirectly by fixed blocking structures are also blocking.

Blocking is first of all a method to prevent the cargo from sliding, but if the blocking reaches up to or above the cargo’s center of gravity it also prevents tipping.

Blocking should be used as far as possible.

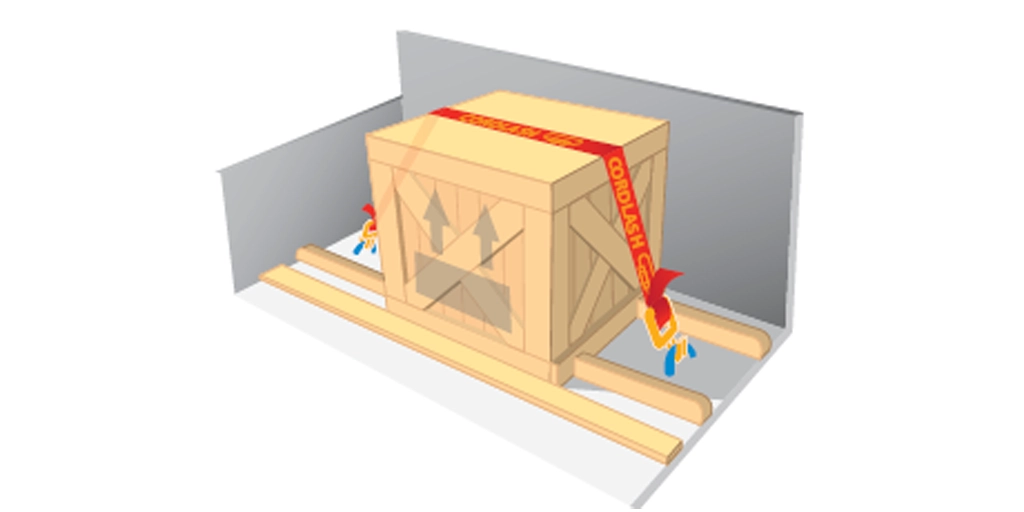

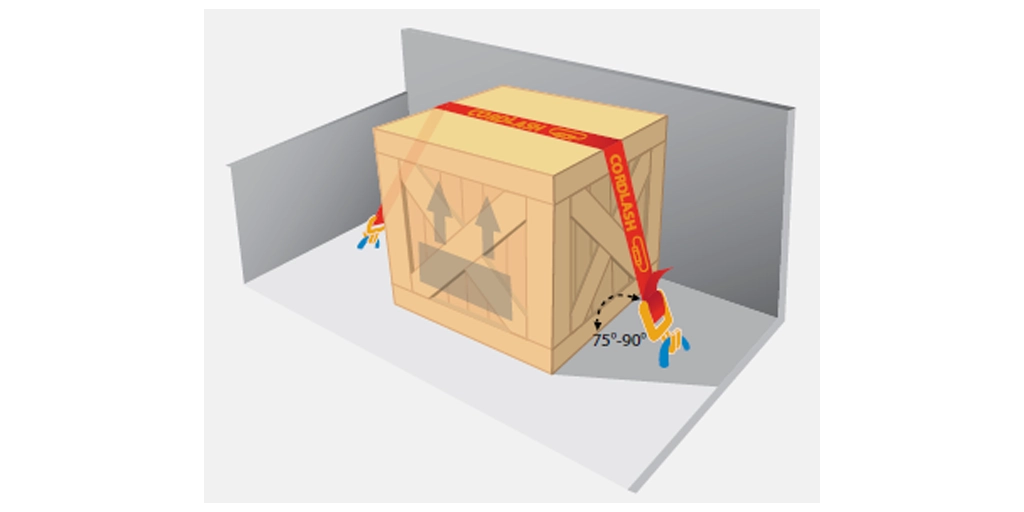

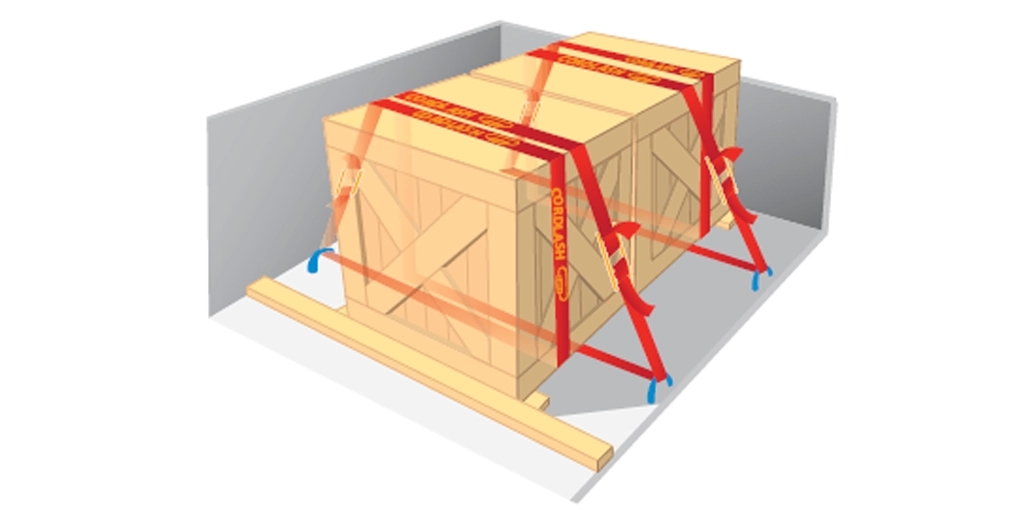

Top-over lashing

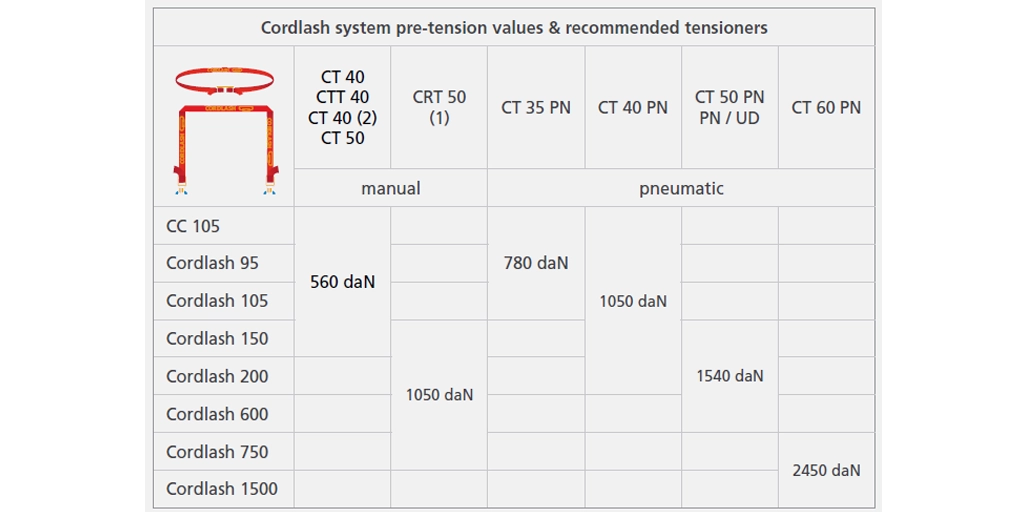

Top-over lashings can be used to prevent sliding and tipping in all directions. It is a method using pre-tension applied to the Cordlash system by either a Cordlash hand or pneumatic tensioner and friction between the cargo and the CTU floor.

Below you will find the conditions under which top-over lashings may be used:

Single top-over lashing using 2 buckle-hooks: When using the tables for topover lashing the angle between the lashing and the platform bed is of great importance. The tables are valid for an angle between 75°- 90°. If the angle is between 30°- 75°, either twice the number of lashings are needed or half of the values in the tables. If the angle is smaller than 30° another cargo securing method should be used!

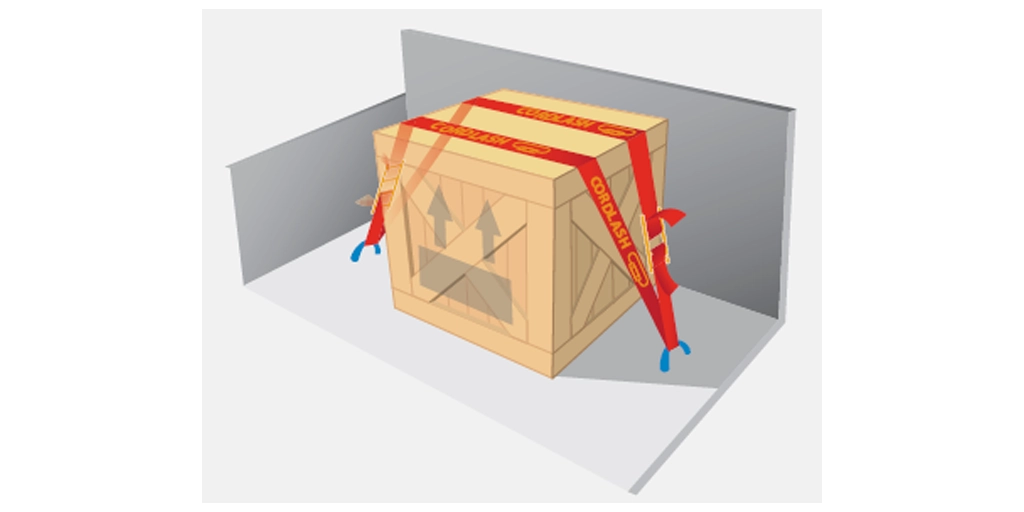

If a double top-over lashing is used, values in the top-over tables may be increased by a factor of 2: The pre-tension values of Cordlash hand and pneumatic tooling is found in the table in section 13. The cargo weights that can be secured using Cordlash tensioners can be found in section 15 per Cordlash cargo securing system. The values are proportional to the tensioners system pre-tension.

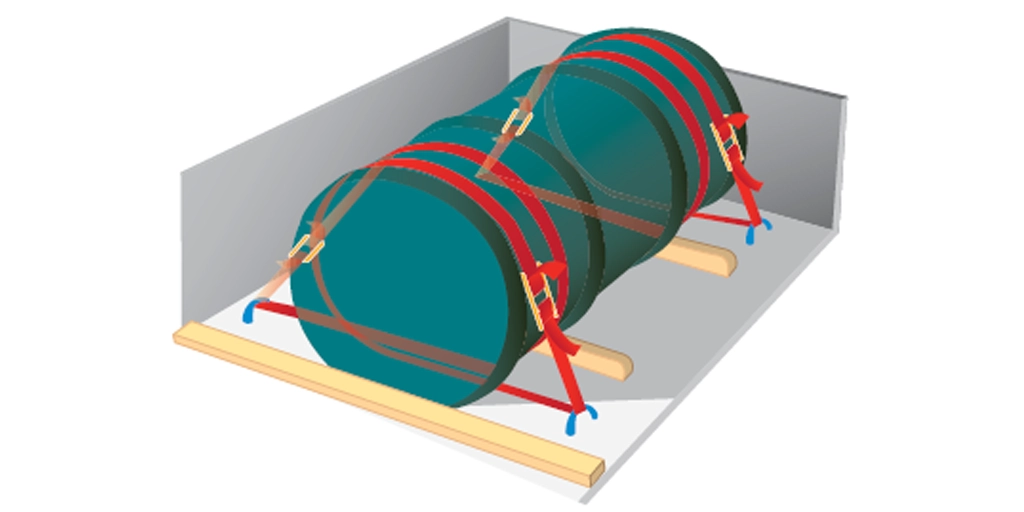

Loop lashing

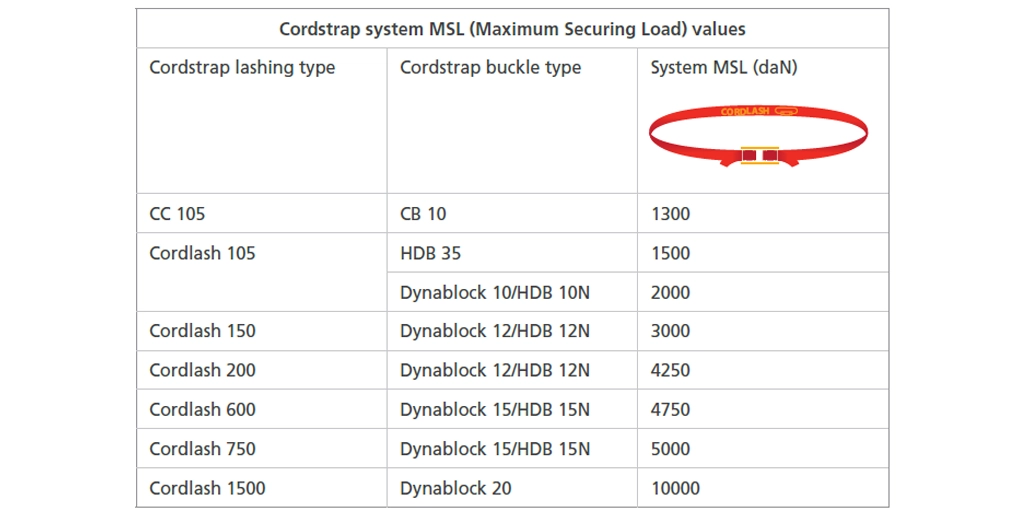

Loop lashings can be used to prevent sliding and tipping sideways. Sliding is prevented by the MSL (Maximum Securing Load) of the Cordlash system. Tipping is however prevented by the system pre-tension applied by either a Cordlash hand or pneumatic tensioner. The conditions under which loop lashing may be used are found below:

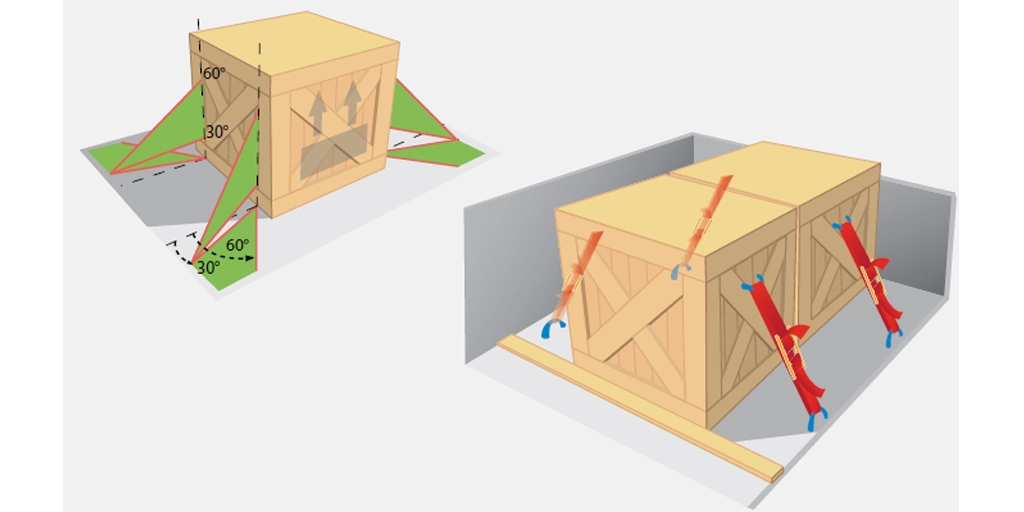

Straight/cross lashing

Straight or cross lashings are used to prevent sliding and tipping in all directions by using the MSL (Maximum Securing Load) of the Cordlash system. The conditions under which a straight or cross lashing may be used are found below.

The tables are valid for an angle of 30 – 60° between the lashing and the platform bed. Sideways/lengthways the lashing angle should also be between 30 – 60°. If the cargo unit is blocked forward and backward, and the lashings are placed with an angle of 90° towards the longitudinal axle the cargo weight in the tables may be doubled.

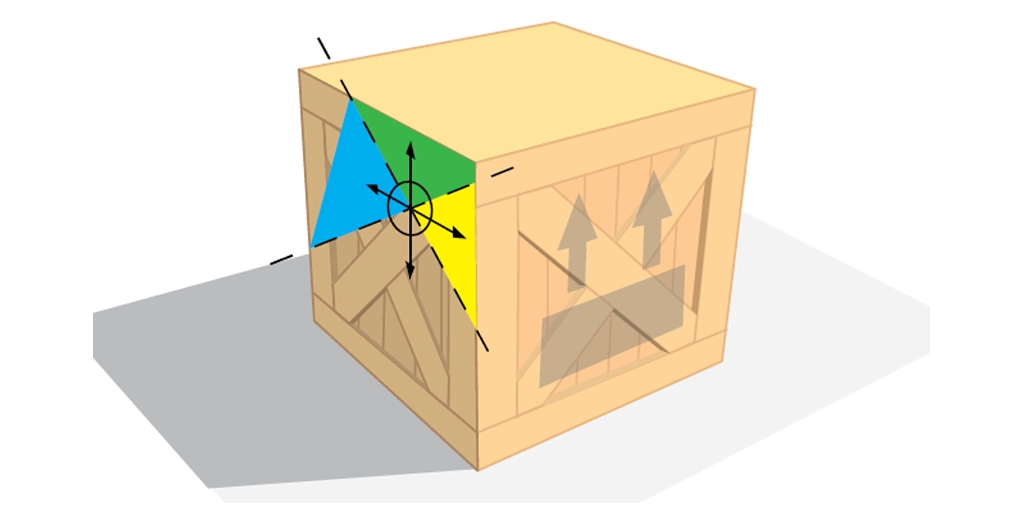

The allowable areas for fixing the lashings on the cargo unit is bounded by straight lines (one for each side), drawn through the center of gravity at an angle of 45°. When the lashings are fixed above the center of gravity, the unit may also have to be blocked at the bottom to prevent sliding.

If one piece of lashing is used between 2 buckle-hooks only 50% of the values in the tables may be used.

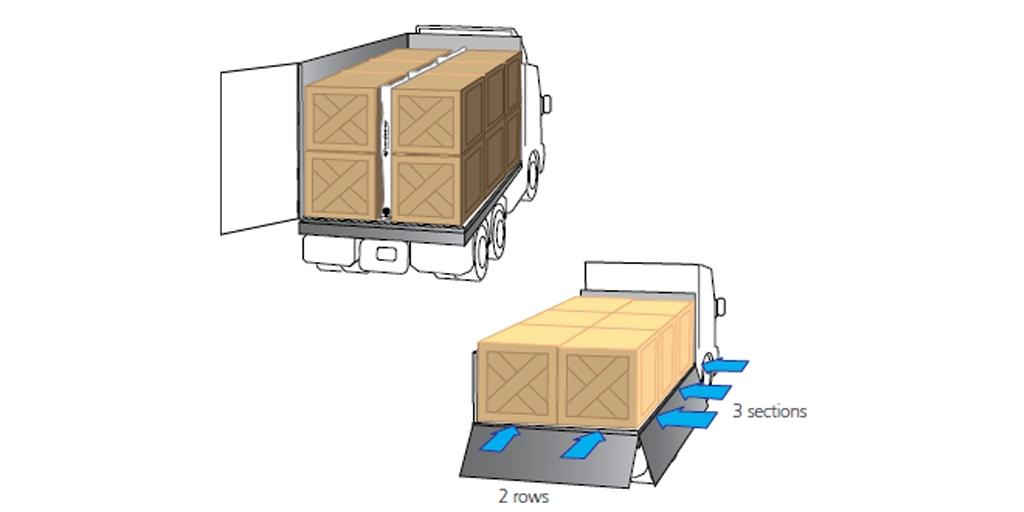

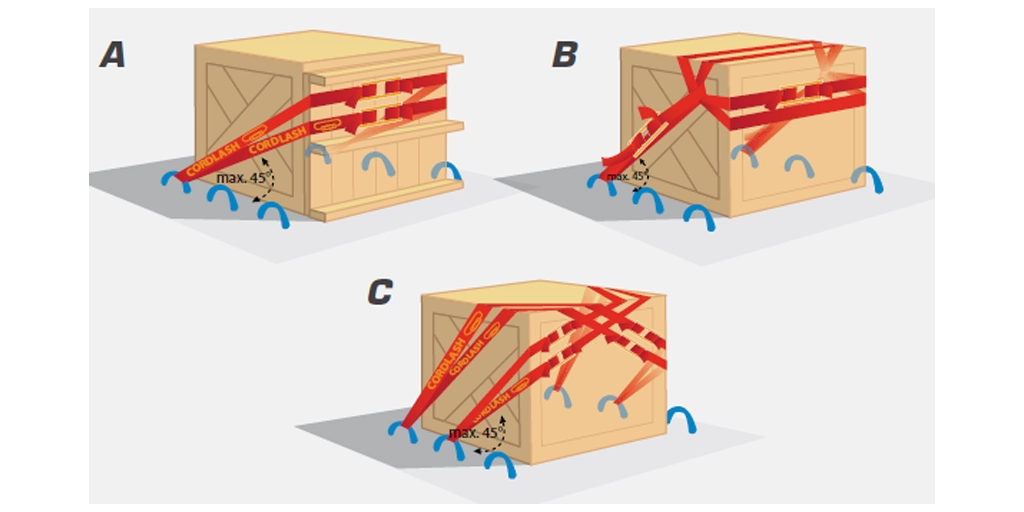

Spring lashing

Spring lashings can be used to prevent sliding and tipping in one direction per lashing either forward, backward or sideward, by using the MSL (Maximum Securing Load) of the Cordlash system. The conditions under which a spring lashing may be used are found below:

Alternative A is not fully effective for avoiding tipping.

Alternative B – the horizontal lashing must be a double looped Cordlash system around cargo

Alternative C has two parts attached to four lashing points and secures twice the values in the tables.

When using a spring lashing to prevent tipping, only the weight of the last section needs to be taken to calculate the number of lashings, not the whole cargo weight!

The angle between the lashing and the platform bed should be maximum 45°. There are a number of ways to apply a spring lashing. If the spring lashing doesn’t act at the top of the cargo the weights in the tables for cargo weights prevented from tipping is decreased.

Note: if one piece of lashing is used between 2 buckle-hooks only 50% of the values in the tables may be used.

Note: if one piece of lashing is used between 2 buckle-hooks only 50% of the values in the tables may be used.

Note: If Cordlash is used as a double top-over system as shown in the symbols below, the values in the tables in section 15 may be doubled.

Share this page