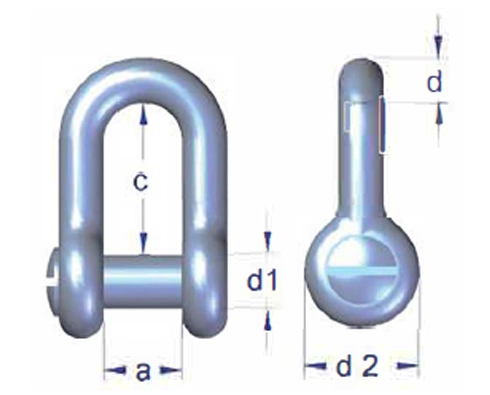

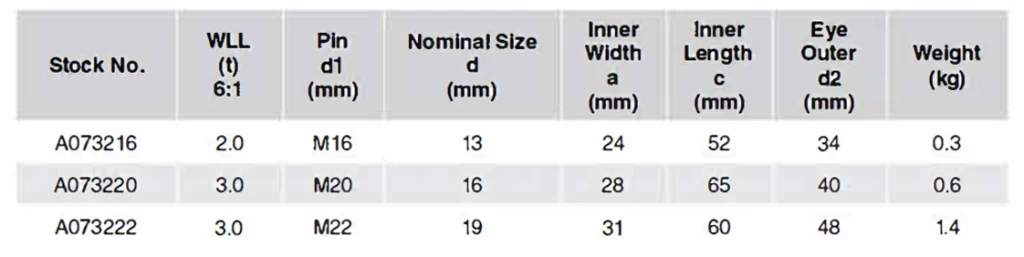

Stainless Steel Shackle No 732 Dee shackle with countersunk pin

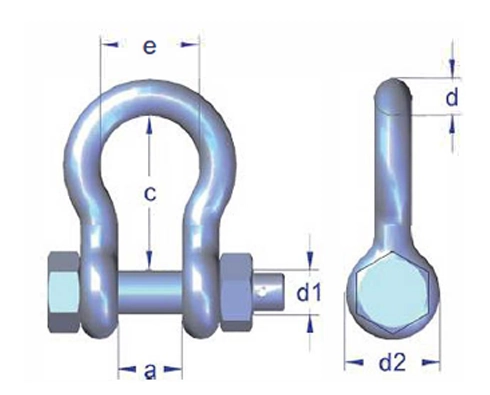

Material : AISI 316

Finish : Highly polished

Design Factor : 6:1

Documentation : Test certificate supplied upon request.

Split pin included

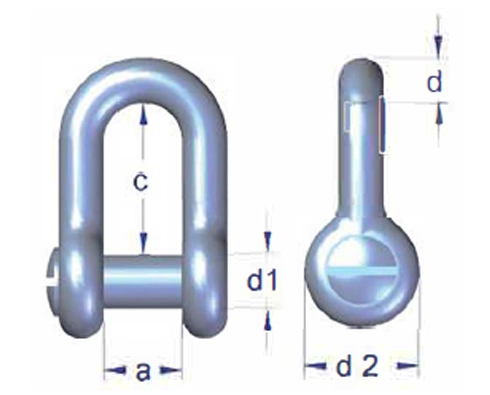

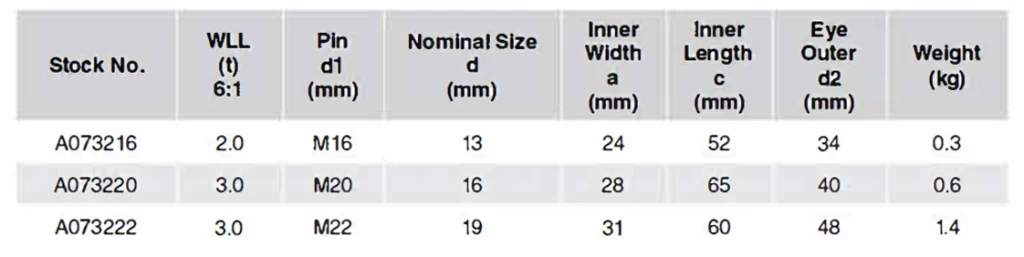

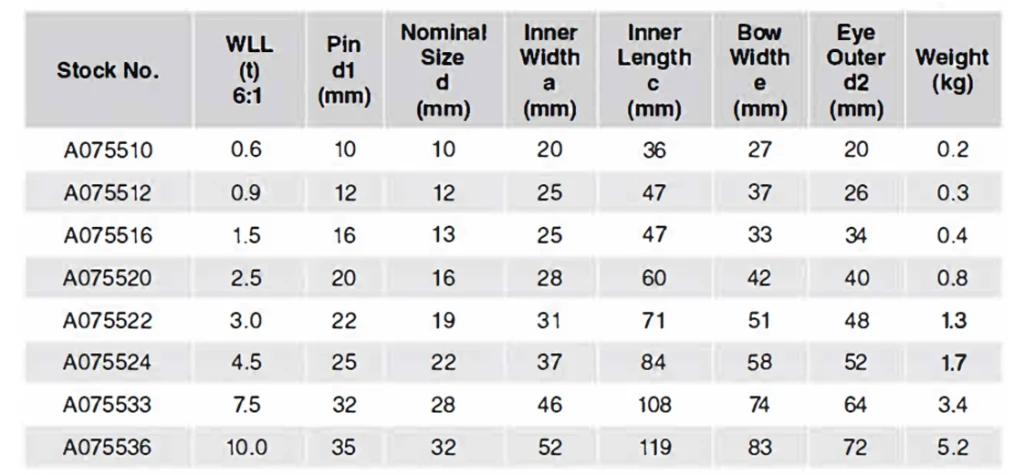

Material : AISI 316

Finish : Highly polished

Design Factor : 6:1

Documentation : Test certificate supplied upon request.

Split pin included

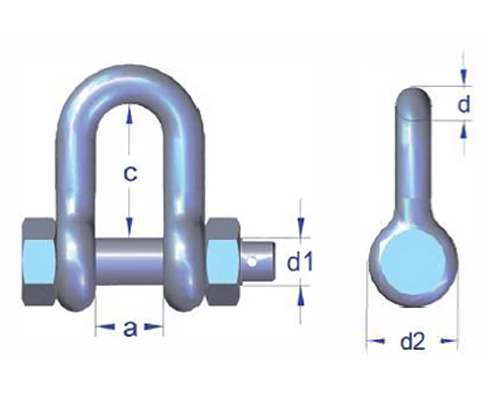

Material : AISI 316

Finish : Highly polished

Design Factor : 6:1

Documentation : Test certificate and traceable 3.1 certificate supplied upon request.

Split pin included

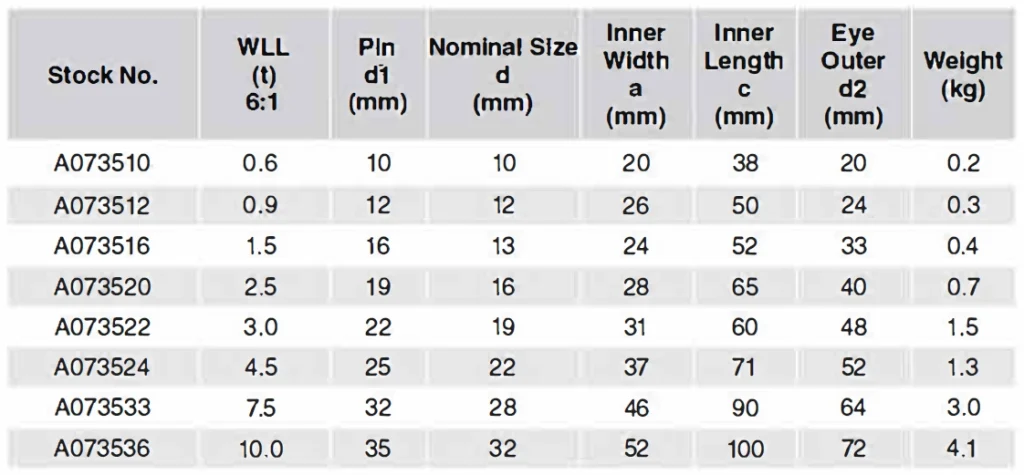

Material : AISI 316

Finish : Highly polished

Design Factor : 6:1

Documentation : Test certificate and traceable 3.1 certificate supplied upon request.

Split pin included

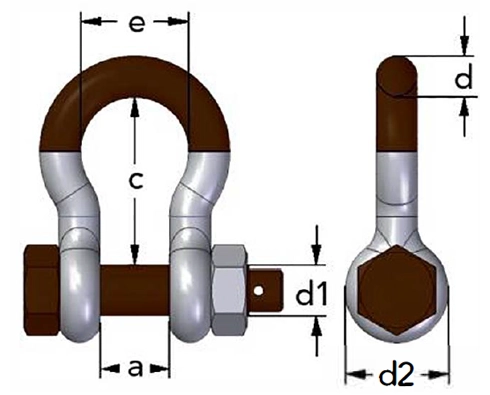

In certain situations a demand for extra Working Load Limit occurs in others the lifting environment has limited space for the lifting application. The 858 Super Shackle enables a higher working load limit for the same nominal size.

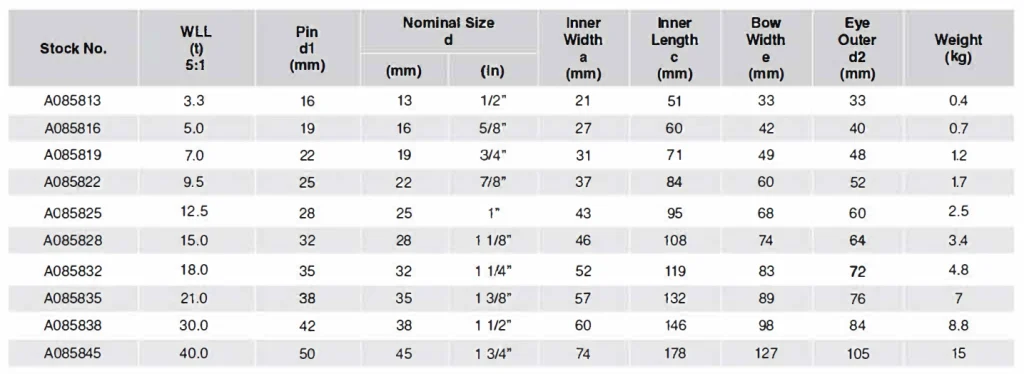

The Super shackle meets the US Federal Specification RR.C-271. It is a grade 8 shackle and has all parts hot dipped galvanized, including the safety bolt.

Standard : US Federal Spec. RR.C-271 Type IVA Class 3, Grade B

Material : High tensile steel. Quenched & Tempered, Grade 8

Finish : All parts hot-dip galvanized + brown color marking

Design Factor : 5:1

Documentation : Test certificate and traceable 3.1 certificate

Temperature :-40°C to 200°C

Split pin included

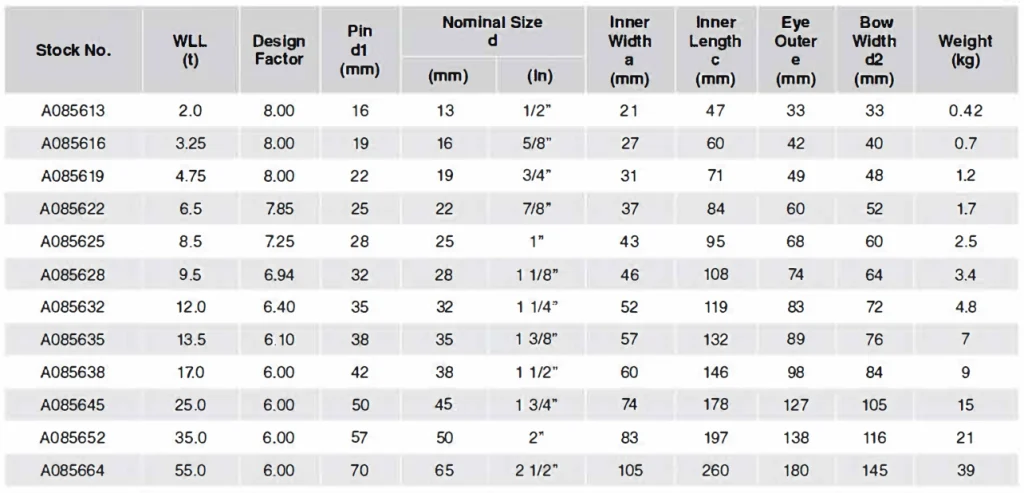

Adverse weather and rough sea conditions in combination with extremely low temperatures, as often encountered for instance in the North Sea, places tough requirements on the products used. 856 Arctic shackles are specially designed for these conditions. The Arctic Shackle is type approved to DNV 2.7-1 Offshore containers and meets the impact requirements of 42 J at – 40 degrees 2C.

The Arctic Shackle is a grade 8 shackle with all parts hot-dip galvanized, including the safety bolt, and has the characteristic brown color marking.

Standard : DNV 2.7-1, US Federal Spec. RR.C-271 and EN-13889

Material : Special alloy steel, Quenched & Tempered, Grade 8

Finish : All parts hot-dip galvanized+ brown color marking

Design Factor : As specified in the table below

Documentation : Test certificate and traceable raw material I inspection certificate acc. EN 10204 – 3.1.

DNVGL-ST-E271-2.7-1 and E273-2.7-3 Type Approval Certification.

Temperature : – 40°C to 200°c

Split pin included

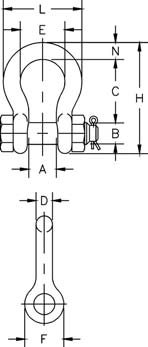

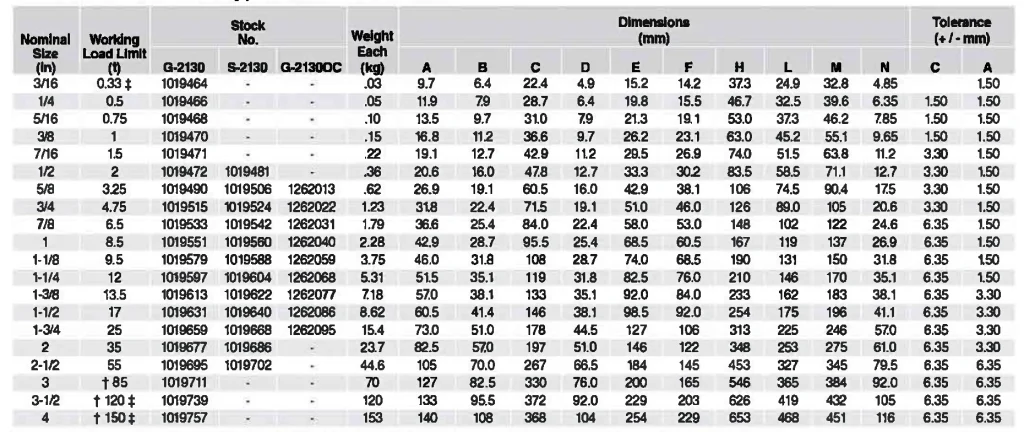

G-2130 / S-2130 Bolt Type Anchor Shackles

6:1 Design Factor. Maximum Proof Load Is 2 times the Working Load Limit. For Working Load Limit reduction due to side loading applications, see Warnings & Applications ..

t lndividually Proof Tested with certification. t Furnished with eye bolts for handling.

G-213

Round pin anchor shackles meet the performance requirements of Federal Specification RR-C-271G, Type IVA, Grade A, Class 1, except for those provisions required of the contractor.

WLL (t) : 0.5 – 35

G-209

Screw pin anchor shackles meet the performance requirements of Federal Specification RR-C- 271G, Type IVA, Grade A, Class 2, except for those provisions required of the contractor.

WLL (t) : 0.33 – 55

G-2130

Bolt type anchor shackles meet the performance requirements of Federal Specification RR-C-271G, Type IVA, Grade A, Class 3, except for those provisions required of the contractor.

WLL (t) : 0.33 – 150

G-210

Screw pin chain shackles meet the performance requirements of Federal Specification RR-C-271G, Type IVB, Grade A, Class 2, except for those provisions required of the contractor.

WLL (t) : 0.5 – 55

G-215

Round pin chain shackles meet the performance requirements of Federal Specification RR-C-271G, Type IVB, Grade A, Class 1, except for those provisions required of the contractor.

WLL (t) : 0.5 – 35

G-2150

Bolt type chain shackles meet the performance requirements of Federal Specification RR-C-271G, Type IVB, Grade A, Class 3, except for those provisions required of the contractor.

WLL (t) : 0.5 – 85

To purchase Shackle products please contact your account manager or contact us today for expert advice and quotation.

Java, Kalimantan and surrounding areas

Andreas Tri J.

Email : andreastj@galangusaha.com

Phone : +628117770126

Java, Kalimantan and surrounding areas

Jonathan Nugroho

Email : jonathan@galangusaha.com

Phone : +628117750906

Batam and surrounding areas

Septyo Setiawan Junior

Email : tyojunior@galangusaha.com

Phone : +6281365295255

All email CC to : sales@galangusaha.com

Share this page

Cordstrap lashing buckles are manufactured from high quality steel and are available in different sizes and strengths. They can be used with Cordlash composite and woven lashing.

The latest innovation in heavy duty buckle technology, the dynamic load buckle is designed for heavy dynamic loads. It offers the highest degree of strength and security available in the polyester lashing industry. Dynablock buckles are manufactured from high quality steel and are available in different sizes and strengths. They can be used with Cordlash woven and heavy duty lashing.

Manufactured from high quality steel and available in different sizes and strengths. Our buckle hooks are designed for use with Cordstrap Lashing, Strapping and Lashing buckles.

AbraWheels Fibre Disc are made with high Quality aluminium oxide ideal for grinding of steel, welds, metal finishing and structural fabrication.

Bolt type anchor shackles meet the performance requirements of Federal Specification RR-C-271G, Type IVA, Grade A, Class 3, except for those provisions required of the contractor.

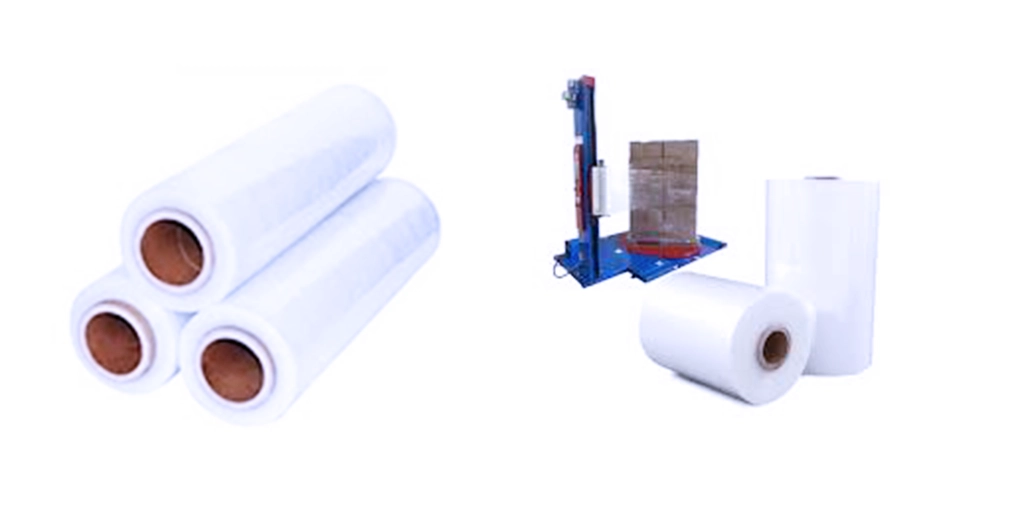

Machine Stretch Film is a high-performance stretchable plastic film designed for use with automatic and semi-automatic wrapping machines. It provides excellent load stability, protection, and efficiency in packaging operations.

Manual Hand Stretch Film is a versatile and easy-to-use packaging solution designed for manual wrapping applications. Made from durable LLDPE material, it offers excellent stretchability, clarity, and resistance to tearing, ensuring secure packaging for goods of all shapes and sizes.